- Home

- Generator Wet Scrubber

Generator Wet Scrubber

Revolutionizing Emission Control: Generator Wet Scrubbers

Introduction

In the realm of power generation, maintaining environmental sustainability is paramount. As generators play a crucial role in producing electricity, addressing emissions from these sources is essential for minimizing environmental impact. This is where generator wet scrubbers emerge as a groundbreaking solution, revolutionizing emission control in power generation facilities.

Understanding Generator Wet Scrubbers

What are Generator Wet Scrubbers?

Generator wet scrubbers, also known as flue gas desulfurization (FGD) systems, are innovative technologies designed to reduce emissions of harmful pollutants from generator exhaust gases. These pollutants primarily include sulfur dioxide (SO2), which is a byproduct of combustion processes in fossil fuel-based generators.

How Do Generator Wet Scrubbers Work?

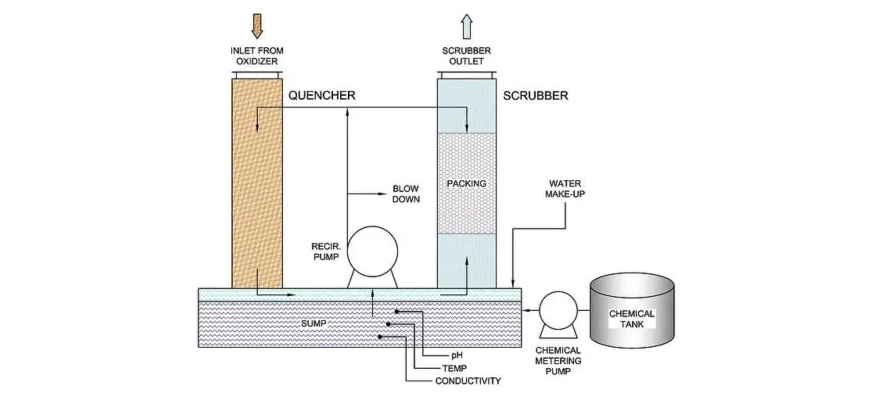

The operation of generator wet scrubbers involves the injection of a water-based sorbent, such as limestone slurry or lime, into the flue gas stream emitted from the generator. As the flue gas passes through the scrubber, it reacts with the sorbent, resulting in the conversion of sulfur dioxide into sulfate compounds or other inert substances. This chemical reaction effectively removes sulfur dioxide and other pollutants from the exhaust gas stream.

Advantages of Generator Wet Scrubbers

Emission Reduction

One of the primary advantages of generator wet scrubbers is their ability to achieve significant reductions in emissions of sulfur dioxide and other pollutants. By effectively capturing these pollutants, wet scrubbers help power generation facilities meet stringent emissions regulations and mitigate their environmental impact.

Improved Air Quality

The implementation of generator wet scrubbers leads to a noticeable improvement in local air quality by reducing the release of harmful pollutants into the atmosphere. This benefits not only the surrounding environment but also the health and well-being of nearby communities.

Regulatory Compliance

Power generation facilities are subject to strict environmental regulations governing emissions of pollutants such as sulfur dioxide. Generator wet scrubbers enable these facilities to achieve regulatory compliance and avoid potential fines or penalties associated with non-compliance.

Types of Generator Wet Scrubber Systems

Spray Tower Scrubbers

Spray tower scrubbers utilize a vertical vessel in which generator exhaust gases are brought into contact with a spray of scrubbing liquid, typically water or a reagent solution. The intimate contact between the gas and liquid phases promotes the absorption of pollutants, resulting in cleaner emissions.

Venturi Scrubbers

Venturi scrubbers utilize a converging-diverging nozzle to create a high-velocity spray of scrubbing liquid, which is injected into the generator exhaust gas stream. The turbulent mixing and collision between the liquid droplets and gas particles facilitate the removal of pollutants through impaction and interception mechanisms.

Conclusion

Generator wet scrubbers represent a significant advancement in emission control technology, offering power generation facilities a reliable and efficient means of reducing environmental impact. By effectively capturing pollutants such as sulfur dioxide, these systems contribute to cleaner air, improved public health, and regulatory compliance. As the demand for sustainable energy solutions continues to grow, generator wet scrubbers will play an increasingly vital role in shaping the future of power generation.